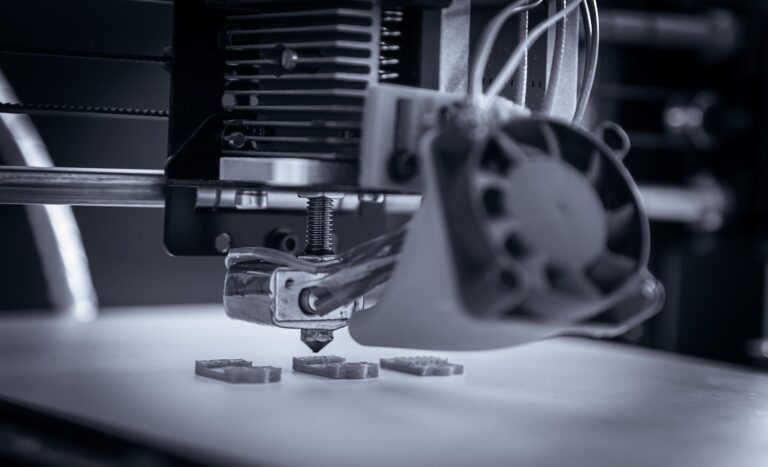

Driven by the global industrial wave and the upgrading of “smart manufacturing”, the demand for plastic shells and components in medical devices, artificial intelligence, new energy vehicles, smart wearable devices and other fields is surging, and the forms are becoming more and more diversified. In the face of different needs from rapid prototyping to mass production, the choice of manufacturing process becomes crucial: large quantities can choose steel injection molding, aluminum mold, low-pressure injection or blister molding; while the rapid prototyping (Rapid Prototyping) stage, 3D printing and CNC machining is a common choice.

So where does silicone replica molding (vacuum casting) shine as the best manufacturing solution for you? MetaMotion, which has been in the field of rapid prototyping and small batch production for 18 years, has refined the following core application scenarios for you to accurately solve your product development pain points:

🏆 1. The absolute king of small-lot production: the perfect choice for low cost and high flexibility

When you are faced with a limited number of production needs, the traditional steel mold injection molding often means a high upfront investment in molds and very low modification flexibility, a huge financial risk. At this time, the silicone re-molding process, with its extremely low tooling costs and excellent rapid response capability, has become the ideal solution for low-volume manufacturing. Typical application scenarios include:

New product marketing and user testing: For example, you have developed an innovative smart home controller (prototyped as the “NexusHome Control”) and urgently need 50-200 sample units to exhibit at the Consumer Electronics Show (CES) or to distribute to potential partners (e.g., U.S. retailer BestTech) to gather feedback. Silicone re-molding allows for quick delivery of near-final injection molded parts in terms of quality and appearance.

Rapid design iteration: Imagine that the Swiss medical device company “SolisMed” takes a liking to your portable monitor design, but wants to add elements of its branded UI or improve the ergonomics of one of the buttons. Using silicone re-molding, MetaMotion responds quickly to the need for modification, updating the design drawings and delivering a new version of the sample in just 1-2 weeks, at a much lower cost than re-molding a steel mold. This design freedom is as flexible as clay.

Specific market segments/customized products: High-end professional audio accessories, limited edition drone housings, specialized grips for specific industrial testing equipment, etc. The market demand is clear but the total volume is small (usually 50-500 sets). Silicone re-molding is the king of price/performance ratio for small batch customized production.

Medical and cosmetic devices: This sector is particularly dependent on the silicone molding process. Demand for a new physical therapy device or skin tester may be in the hundreds of units range during the introductory phase of the market. The high cost of medical device certification and cautious marketing strategies make it extremely risky to invest in large-scale molding upfront. Silicone replica molds provide high-quality, fully functional parts that perfectly fit the needs of medical device prototyping and initial small-volume launch, making them the preferred process for medical-grade rapid prototyping.

✅ Silicone remolding offers significant advantages:

Low-Cost Tooling: Typically a fraction of the cost of steel molds.

Short Lead Time: From prototype to small-volume finished product, much faster than traditional molding.

High Flexibility for Design Changes: Design optimization accelerates time-to-market by eliminating the need to incur large tooling scrap losses.

Near-Production Quality: Wide selection of materials (e.g. ABS, PC, PP, soft TPU, even high temperature resistant materials, transparent materials) and excellent surface treatment (painting, silk-screen printing, electroplating) are sufficient for function testing, market demonstration and early sales.

🚀 2. Conquering large and complex structures: breaking through the “mission impossible” of steel mold costs

When your products are large equipment shells, complex one-piece structural parts (such as interior parts of new energy vehicles, drone bodies, large instrument panels), the cost of steel molds may reach millions or even tens of millions of RMB. This is an unaffordable burden for most enterprises and projects (except for some cost-neutral national projects).

Silicone re-molding technology shows revolutionary cost advantages in such scenarios:

Drastically Reduced Tooling Investment: The cost of a large silicone mold, even taking into account possible reinforcing structures, is much lower than that of a steel mold of the same size, reducing the risk of upfront investment to a minimum.

Material Utilization and Process Optimization: For large parts, MetaMotion can further optimize costs by using specially degassed recycled silicone material in non-critical stress areas of the mold (to ensure that the quality of the final part is not compromised). At the same time, the tooling cycle can be partially overlapped with the first product validation cycle to effectively manage the overall project timeline.

Complex Geometry in Single Piece: The exceptional flexibility of silicone molds allows them to perfectly replicate extremely complex details, deep cavities, inverts and internal structures. For example, the complex internal ductwork of an aircraft interior ventilation system housing called “AeroDynamics” would have cost an astronomical amount of money if it had been molded in steel, and the airtightness and strength would have been compromised if it had been assembled in pieces. Vacuum casting, on the other hand, allows for one-piece molding, ensuring structural integrity and functionality. Design freedom is completely released at this moment.

✅ The advantages of silicone re-molding are highlighted:

Break Cost Barriers: Make prototyping and low-volume production of large, complex products economically viable.

High Fidelity for Complex Details: Solve complex geometries that are difficult or costly to achieve with steel molds.

Lightweight Large Part Manufacturing: Ideal for producing large, weight-sensitive prototypes or end parts.

Accelerate Large Projects: Avoid lengthy mold design and manufacturing cycles.

⚙️ 3. CNC machining “headache” of complex small parts: Silicone replica mold accuracy and strength to the rescue!

Even CNC machining, which is an excellent tool for rapid prototyping, will encounter bottlenecks when facing some special small and complex functional parts:

Limited Tool Access: The extremely fine ribbing, deep holes, or complex surface intersections inside the part may be inaccessible to the CNC tool or may lack sufficient machining space, resulting in no machining or a serious loss of accuracy.

Weakness from Assembly: Breaking a small part into smaller parts for the purpose of machining, and then gluing or welding the assembly, can significantly reduce overall structural strength and reliability, affecting functional testing and even safety in use. For example, a miniature multi-joint connector on a minimally invasive surgical instrument.

High Labor Costs and Time Consumption: CNC programming, clamping, machining and post-processing of complex small parts are often time-consuming and labor-intensive, with high labor costs.

This is where silicone remolding offers a superior solution:

Handles Internal Complexity: No matter how complex the internal structure is (e.g. micro gearbox housing, precision connector), as long as the prototype (master) can be created (usually through high precision 3D printing such as SLA/DLP or micro-nano CNC), silicone molds can be perfectly replicated, one-shot, no need to dismantle the part. This is particularly suitable for miniature medical device components, precision electronic housings, complex snap structures, etc.

Maintains Structural Integrity: One-piece molded parts eliminate potential weaknesses and failure risks associated with subassemblies and assemblies, ensuring functional structural integrity.

Functional Accuracy Achieved: Modern vacuum casting processes combined with high quality engineering resins (such as PPO-like materials, high-temperature epoxy resins, or high-toughness polyurethane) can achieve very high dimensional stability (±0.15mm/100mm or higher depending on the material and process control), which is sufficient to satisfy the needs of most Functional prototypes and small-volume end-use parts for assembly and testing.

Cost-Effective for Complexity: For extremely complex, tiny parts, the cost-per-piece and time-efficiency of silicone replicas often outperforms high-precision, multi-process CNC machining, especially when dozens to hundreds of parts are required. This is the smart alternative to complex small part manufacturing.

✅ The advantages of silicone re-molding are outstanding:

Access the Unmachinable: Create complex internal features that CNC tools can’t reach.

Built-in Strength: One-piece molding ensures reliable structural strength for small, complex parts.

Fit for Purpose Precision: Meet the precision requirements of functional assembly and testing.

Mass Production Replacement for Small Complex Parts: Provides a stable supply of small quantities of complex parts.

🔍 4. MetaMotion’s Professional Insight: Golden Rules for Selecting Silicone Re-molding

Summarizing MetaMotion’s 18 years of experience in rapid prototyping and low-volume manufacturing services, the golden rule for selecting silicone re-molding (vacuum casting) is clear:

“Small quantities are a prerequisite: your requirements are usually in the range of tens to hundreds of pieces (classic range: 20 – 500 pieces), up to thousands of pieces (depending on the size and complexity of the parts).

“Flexibility” is a necessity: the product is in the phase of design validation, market testing, user feedback collection, and there is a high probability of design modifications.

“Cost is a bottleneck: High mold costs make it difficult to start a project, or the ROI cannot support traditional molding in small quantities.

“Complexity/Large Size” is a challenge: Products with complex internal and external structures, fine features, deep cavities, or large sizes make molds cost prohibitive or difficult to manufacture.

“Time” is the pressure: the need to respond quickly to the market and shorten the time-to-market.

💎 Conclusion: Silicone Re-molding for the Early Stages of Product Development

In the uncertain early stages of product development and low-volume introduction, silicone molding (vacuum casting) is not a compromise, but a strategic and optimal manufacturing strategy. It’s the optimal strategic manufacturing strategy, balancing cost, speed, flexibility, and quality to eliminate capital risk, accelerate design iteration, and gain a head start in the marketplace.

Whether you’re developing the next generation of smart wearables, a breakthrough medical device, or a key component for a new energy vehicle, when your project meets the Golden Rule, silicone replicas are MetaMotion’s top priority for efficient, reliable, and cost-effective rapid prototyping and low-volume manufacturing. Unlocking design possibilities starts with choosing the right process. Let us help you take your ideas from Prototype to Market with our specialized vacuum casting technology!