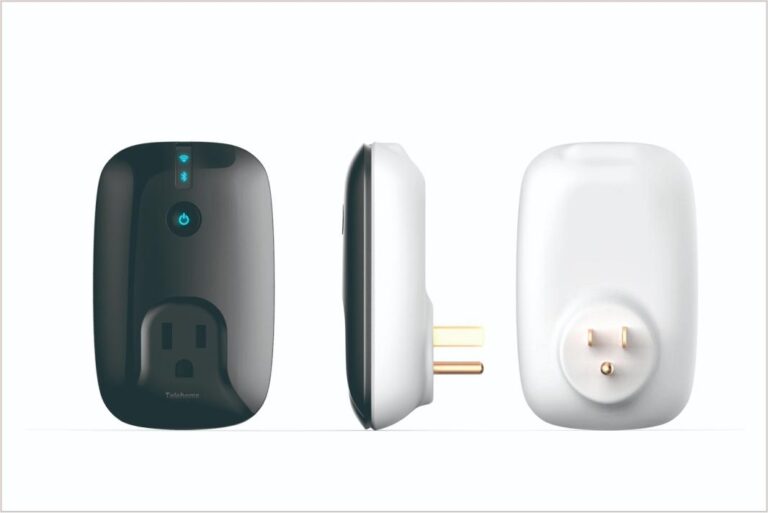

Product Name: UAV rapid prototyping

Material: ABS, PC, Carbon Fiber

Processing Method: CNC Processing, 3D Printing

Processing Cycle: 5 days

Processing Accuracy: 0.03-0.08mm With the quality of living standard getting better and better, the application of drones to the life of the people is more and more, and this is a very good business opportunity for the manufacturers of the production of drones. This is a very good business opportunity for manufacturers of drones, in the research and development of new products will always be the first to consider sampling, that is to say, rapid prototyping, because manufacturers also know that if the direct opening of the mold, the risk is relatively large. The cost and cycle time consume not only money, but also the waste of time. Doing rapid prototyping will reduce the cost of R&D, the cycle time is fast and the accuracy is good.

So what is the process of making rapid prototyping for this drone?

1. Design drawings: generally done with AUTOCAD. Need designers to do, in general, the format of the handboard drawings are mainly .IGS, .STP, .STL, .PRT, .X-T and so on. (Design drawings are generally given by customers to rapid prototyping factory for processing)

2. Programming: The programmer analyzes the 3D data and writes the program language to control the CNC machining center.

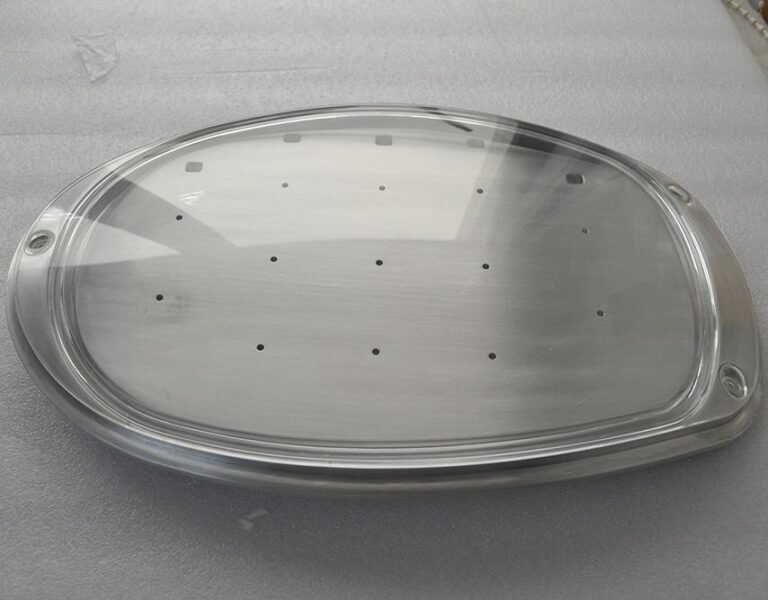

3. Processing: Execute the program commands, exactly should be like this – CNC machine tool in accordance with the path set by the program, in the plastic material above the back and forth carving, the excess part removed, so as to get the plastic rapid prototyping .

4. Polishing: After a part is processed on a CNC machine, there will be a lot of burrs and knife marks on the surface of the part. It is impossible to rely on these machines. So it needs human hand to deal with these problems. Usually, they are polished with polishing paste or sanded with sandpaper. The problem should be noted when sanding, first you need to do a rough sanding with a very coarse sandpaper. Remove the surface of the layer of very coarse burrs before sanding.

5. Oil spraying: CNC rapid prototyping can be sprayed with color according to the color Pantone number provided by the customer. It can be sprayed in matte color and glossy.

6. Screen printing: many companies have their own brands, in CNC rapid prototyping also need to print the company logo or product model in CNC rapid prototyping sample

7. Assembly: that is, the plastic rapid prototyping of the various components are assembled, after processing is the assembly of the problem of data testing.