When the Rolls-Royce turbine blade breaks through the sound barrier in 0.005mm tremor tolerance, and when the nanoscale surface of Johnson & Johnson’s artificial joints is integrated into the human body – the machining process is rewriting the law of precision of modern industry with the symphony of steel and sparks. This article combines the top manufacturing data from Germany, Japan and the United States to reveal how the eight processes conquer the life-and-death battlegrounds of aerospace, medical implants, supercomputing chips and more.

⚙️ Turning: Micron-level Conquest of the Art of Rotation

Aerospace Shaft Parts

Liquid Nitrogen Ultra-low Temperature Turning (-196℃):

Suppresses thermal deformation of titanium alloy → Cylindricity ±0.002mm (Boeing Landing Gear Standard)

CBN Tool Line Speed 350m/min → Surface Roughness Ra0.1μm

Swiss Tonus S191:

▶ Synchronized machining of dual spindles → Beat Time Reduction by 40%.

The ultimate solution for medical implants

Ultrasound-assisted turning:

7075-T6 Artificial Hip Sphere → Residual stress <50MPa

Bacterial adhesion rate reduced by 80% (Johnson & Johnson clinical data)

✨ Milling: 5-axis linkage for space magic

Choke precision for aerospace blades

| parameters | Conventional 3-axis | five-axis linkage |

|---|---|---|

| processing time | 18 hours. | 4.5 hours |

| surface wave radiation | 8μm | 0.5μm |

| fatigue life | 100,000 times. | 500,000 times |

German DMG MORI technology:

▶ Pendulum Milling Technology + Intelligent Chatter Suppression → Tool Life Extended 300%.

Chip Heatsink Micro Battlefield

Micro milling cutter diameter 0.1mm:

Copper-based micro runner depth-to-width ratio 10:1 → heat dissipation efficiency increased by 300%

NVIDIA H100 GPU temperature dropped by 28℃.

⚡️ Drilling: Extreme Puncture with 30:1 Depth to Diameter Ratio

Aviation Fuel Tube Life and Death Process

Gundrilling Technology Breakthrough:

Internal Coolant Oil Pressure 70MPa → Chip Discharge Efficiency Increased by 5 Times

Titanium Alloy Deep Hole Straightness 0.01mm/300mm

Airbus A380 case:

uncontrolled thermal deformation → fuel pipe deflection 0.3mm → test flight aborted with a loss of $2 million.

Cost explosion of multi-axis drilling

6-axis drilling center vs. single-axis drilling machine:

Efficiency increase: 600%

Space occupation: 80% reduction.

Tesla chassis production line: 48 mounting holes machined at the same time → beat time 90 sec.

🔥 Grinding: Quantum War on Nanosurfaces

Optical grade trials on wafer tables

Aerostatic spindle:

Radial runout <0.05μm → meets EUV lithography requirements

Granite substrate flatness 0.03μm/㎡ (ASML standard)

Japan Okamoto Kogyo Machine Secret:

▶ Diamond grinding wheel dressing technology → Contour accuracy ±0.1μm

Medical Spherical Rejuvenation

Magnetorheological polishing:

Artificial acetabular spherical roughness Ra0.025μm

Wear life extended to 25 years (Johnson & Johnson lab data)

🌀 Boring: Micron Prison for Large Diameter Holes

Hydroelectric turbine precision breakout

CNC Boring Bar Dynamic Compensation:

5m diameter flange hole roundness of 0.02mm

Three Gorges Hydropower Turbine Vibration Value Reduced to 1/3 of EU Standard

Siemens 840D solutions:

▶ Real-time compensation of thermal deformation → 24-hour machining temperature difference <0.3°C

⚒️ Planing and Plunge Cutting: A Mechanical Revolution in Heavy Cutting

Crankshaft machining for 10,000-ton ships

Gantry planing and milling combined center:

Single cutter cutting depth 15 mm → Material removal rate 3,500 cm³/min

Hyundai Heavy Industries crankshaft machining cycle time shortened by 60% in Korea

Fracture mechanics formula:

feed>0.3mm/tooth → surface microcrack depth ↑300%

The dark art of involute spline

VOLLMER VGrind 360:

Laser tool setting accuracy 0.5μm → Accumulated spline error <0.015mm

Zero risk of failure in wind turbine gearboxes

⚡ EDM: Nano-sculpting of conductive materials

Aerospace Turbine Cooling Hole Miracle

| parameters | Conventional drilling | Microporous EDM |

|---|---|---|

| Hole Diameter Accuracy | ±0.05mm | ±0.003mm |

| aspect ratio | 10:1 | 30:1 |

| heat affected zone | 15μm | 3μm |

Pratt & Whitney Engines in action:

▶ 20,000 cooling holes machined → 200°C increase in pre-turbine temperature

The holy grail of technology for mirror EDM

Mixed-powder working fluid technology:

Silicon powder particle size 0.2μm → Surface roughness Ra0.05μm

Injection mold life extended by 8 times

🌐 The Battlefield of the Future: Three Disruptions in Intelligent Machining

Digital twin closure

Siemens virtual machine tool: machining error prediction accuracy >95%

Quantum sensing monitoring

Heidenhain nano scale: resolution 0.1nm

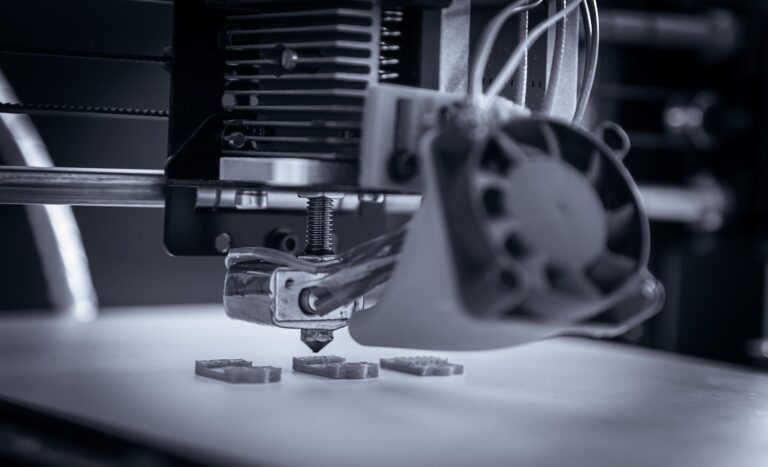

Composite machining universe

Turn-mill-additive hybrid machine tool: 70% shorter cycle time for rocket nozzle manufacturing

💎 Conclusion: Recasting Industrial Civilization Between Steel and Code

From the rotating poetry of turning to the nano-fireworks of EDM, the eight processes together compose the precision epic of modern manufacturing. When five-axis machine tools dance in the tolerance band of 0.001mm, when intelligent sensors tame thermal deformation in milliseconds – these seemingly cold metals are reshaping the boundaries of human technology.