CNC machining

about CNC machining

What is CNC machining Customized?

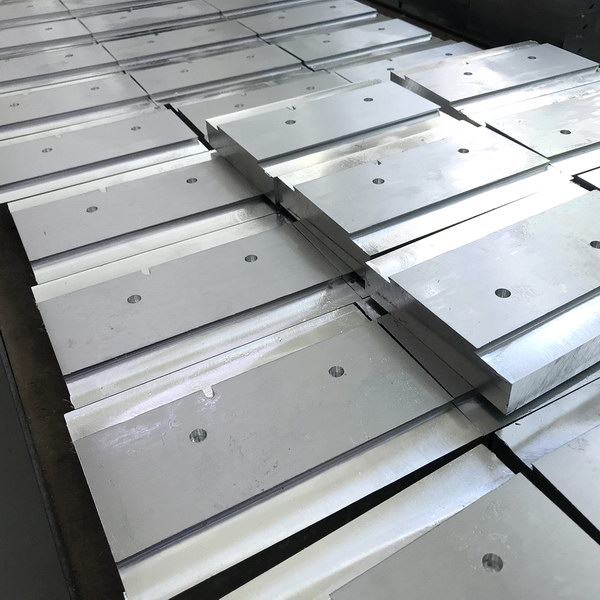

CNC custom machining typically refers to low-volume CNC machining that is performed to a customer’s specific specifications and individual needs, while meeting precise quality, on-time delivery, and cost-effectiveness and affordability.

The benefits of CNC machining align with the low-volume production requirements of customized parts, including accuracy, repeatability, and flexible processes, as well as a wide range of material choices, all of which contribute to getting products to market faster.

Why do you need CNC Custom

Machining?

CNC custom machining is perfect for special order needs, especially when small quantities of parts are required or when lead times and batches are irregular.

Turn to custom machining when parts with special requirements are not available from existing catalog suppliers.

CNC custom machining is a reliable choice when high accuracy and quality parts are required, along with special machining processes and precise repeatability.

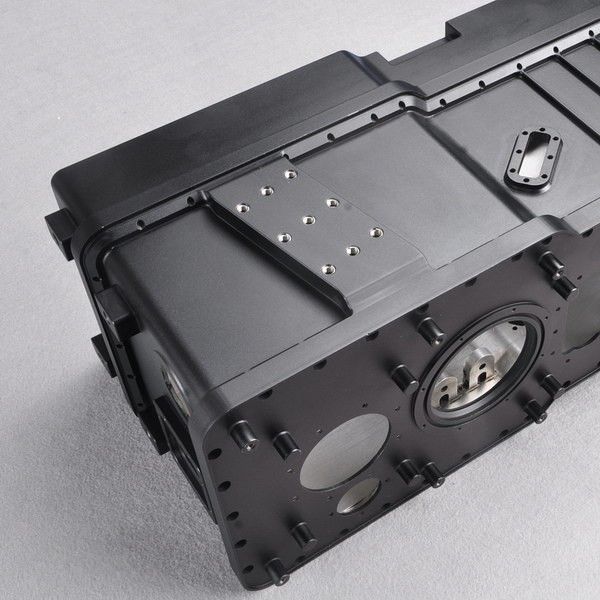

Use CNC custom machining for pre-production while you wait for a mold or die casting die to be produced to get your product to market faster.

CNC Batch Service

Accuracy, Quality, Affordable Prices, Any Lot and Quantity

Our team is ready to respond to all your needs

Choosing the Right CNC Custom Fabricator

Choosing the Right CNC Custom Fabricator

Finding a CNC custom fabricator that offers “build to order” can be a valuable addition to your vendor system.

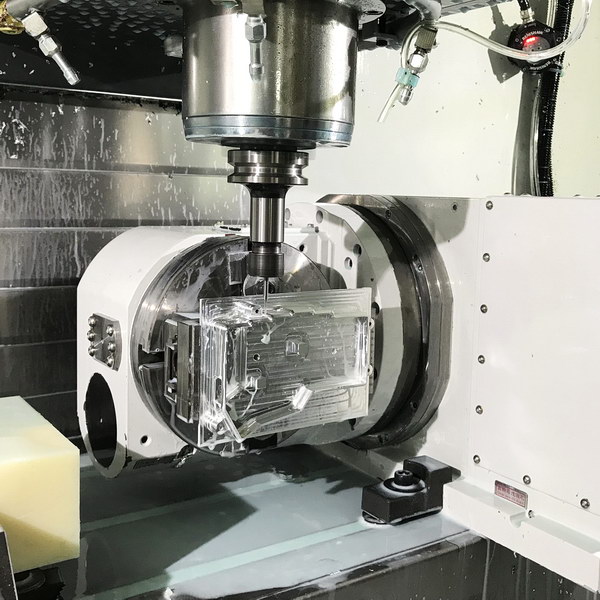

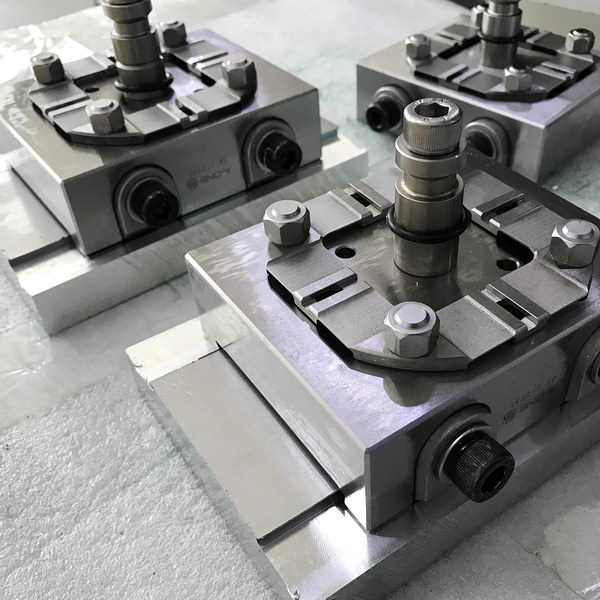

With state-of-the-art machining equipment and flexible production methods, MetaMotion offers a comprehensive portfolio of advantages ranging from simple milled or turned parts to complex and sophisticated 5-axis CNC machining, from prototype plastics machining to precision metal machining. Our custom fabrication shops maintain 24/7 operations for optimal efficiency, quality and process control throughout the entire production process from programming development to machining to post-processing.

Our in-house production capabilities coupled with the ability to consolidate outside manufacturing resources allows us to turn things around quickly to meet any of your custom machining needs. That’s why we’re able to offer you the competitiveness of a low-volume CNC machining program.

CNC machining customized production capacity

Machining technology: milling, turning, 5-axis machining, EDM and wire EDM, surface grinding.

Surface treatment: secondary, primary (natural color) and secondary (black) anodizing; primary and secondary chromate; powder coating; electroplating; paint screen printing.

Materials: Metal materials including aluminum alloys, steel and stainless steel, bronze and brass; plastic materials including ABS, PC, acrylic, nylon, POM, PEEK and PEI.

Inspection: CMM, 3D scanner, full set of measuring equipment, surface roughness tester, hardness tester, etc.

We will work with you to ensure the success of the entire project. Whether manual tooling is required

Reliable and consistent results can be provided in a timely manner for type, custom equipment and mass produced parts.

Submit an inquiry and let’s get the discussion started!