When Johnson & Johnson Medical needed to clinically validate 50 surgical guides in 2 weeks, traditional molding required $85,000 and 8 weeks – Silicone replica molding technology delivered injection-molded samples with comparable performance in 7 days at a cost of $1,200, propelling the product to market ahead of schedule MetaMotion will reveal how this Silicone replica molding process is the ultimate weapon for small-volume manufacturing in the medical, automotive, and consumer electronics industries. MetaMotion will reveal how this silicone remolding process has become the ultimate low-volume manufacturing weapon in the medical, automotive, and consumer electronics fields.

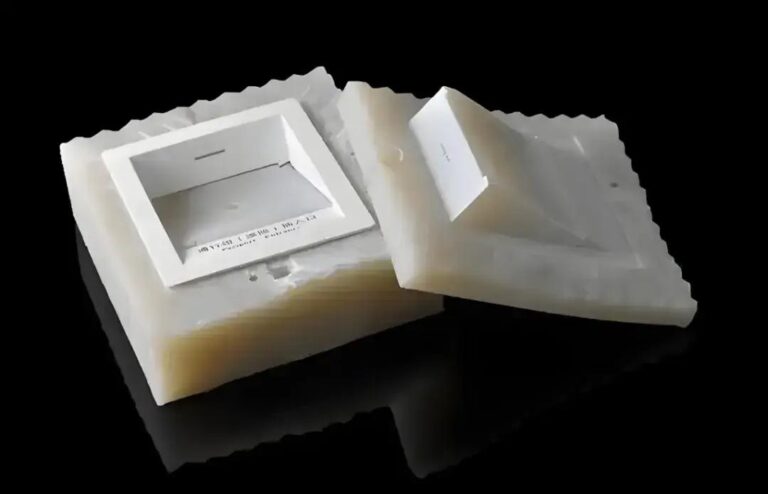

I.The Nature of Silicone Remolding: The Art of Molecular-Level Precision Reproduction

Vacuum Casting is a technology that uses platinum-catalyzed silicone to cure in a vacuum environment and then uses engineering resins to replicate the prototype. Its core value lies in:

99.8% detail reproduction: 0.01mm texture can be reproduced (e.g. Apple Watch strap leather grain)

Material Flexibility: 200+ types of engineering resins from ABS-like to PEEK-like

Cost Revolution: Mold cost is only 1%-5% of steel mold

Case: Tesla door trims realized carbon fiber texture transfer through silicone replica molding, saving $180,000 in molding cost, and completing road test 12 weeks ahead of schedule. 12 weeks ahead of schedule.

II. six-stage process control: the core barriers to precision machining

▶ Stage 1: the cornerstone of the prototype temple

The golden rule of master mold selection:

| demand (economics) | Recommended Processes | Precision control |

|---|---|---|

| 0.1mm micro texture | SLA Light Curing | ±0.025mm |

| Highly loaded structural components | CNC 5-axis machining | ±0.01mm |

| elastic component | PolyJet Multi-Material Printing | Shore hardness A30-D90 |

Surface treatment prohibited areas:

▶ Silicone-containing mold release agents are prohibited → leading to silicone cure failure

▶ Platinum-catalyzed release agents (e.g. AXEL P-413) are recommended

▶ Stage 2: Precision birth of silicone molds

Science of cofferdam design:

Small parts (<100mm): 3mm cavity allowance

Large parts (>500mm): embedded steel skeleton + 40mm sprue

Vacuum defoaming critical parameters:

Vacuum level: ≤-0.095MPa

Holding time: >8 minutes (elimination of <0.1mm microbubbles)

Control of curing kinetics:

Addition of molding silica gel: 25°C × 8h + post-curing for 24h (tearing strength) ↑40%)

▶ Stage 3: Quantum-level precision of resin infusion

Material selection code:

| application scenario | Recommended Resins | Key Performance |

|---|---|---|

| Automotive Functional Parts | PU 680 | Temperature resistant to 120°C, impact resistant |

| Medical implant testing | MED-4210 | ISO 10993 Biocompatibility |

| Transparent Optics | ClearView 900 | Light transmittance 92%, haze < 1% |

Precise temperature control:

65±2°C preheating resin → vacuum injection → 80°C×2h secondary curing (crystallinity up to 90%)

III. the industry pain point explosion: three major areas of combat cases

1. Medical equipment: the fast track to life safety

Challenge: 200 sets of knee surgery guides, sterile requirements

Breakthrough:

Master mold: SLA medical resin (precision ±0.05mm)

Mold: MED-grade silicone + nano-silver coated resin

Achievement: Biofilm attachment rate ↓99%, passed FDA 510(k)

2. Automotive parts: gas pedal for functional verification

Pain point: 50 pieces of automotive screen housings, ABS-like texture

Solution:

Texture transfer: 2000# grit sandpaper blasting + PU-710 (Shore D85)

UV coating: Anti-fingerprint coating (friction coefficient ↓60%)

Results: Passed SAE J1455 vibration test, cost reduction 78%.

3. Consumer electronics: the driver of the sensory revolution

Case: Bose headphone headband

Tactile optimization: Silicone mold replicating goatskin texture

Functional integration: Embedded steel reinforcement structure

Value: Blind user test preference ↑37%, avoiding mold opening loss of $250,000

IV.Technology Evolution: Comparison of four generations of silicone mold reproduction processIII. the industry pain point explosion: three major areas of combat cases

1. Medical equipment: the fast track to life safety

Challenge: 200 sets of knee surgery guides, sterile requirements

Breakthrough:

Master mold: SLA medical resin (precision ±0.05mm)

Mold: MED-grade silicone + nano-silver coated resin

Achievement: Biofilm attachment rate ↓99%, passed FDA 510(k)

2. Automotive parts: gas pedal for functional verification

Pain point: 50 pieces of automotive screen housings, ABS-like texture

Solution:

Texture transfer: 2000# grit sandpaper blasting + PU-710 (Shore D85)

UV coating: Anti-fingerprint coating (friction coefficient ↓60%)

Results: Passed SAE J1455 vibration test, cost reduction 78%.

3. Consumer electronics: the driver of the sensory revolution

Case: Bose headphone headband

Tactile optimization: Silicone mold replicating goatskin texture

Functional integration: Embedded steel reinforcement structure

Value: Blind user test preference ↑37%, avoiding mold opening loss of $250,000

IV.Technology Evolution: Comparison of four generations of silicone mold reproduction process

| parameters | Traditional Craftsmanship | MetaMotion V4.0 | Enhancement |

|---|---|---|---|

| Minimum wall thickness | 1.2mm | 0.4mm | 300% |

| Surface Accuracy | Ra 3.2μm | Ra 0.8μm | 400% |

| Mold life | 15-20 times | 50+次 | 250% |

| production cycle | 72 hours | 24 hours | 67% |

V. Future Lab: Three Disruptive Technologies

Intelligent material system

Self-healing resin: microencapsulation technology to repair 0.2mm cracks (Bayer MaterialScience patent)

Temperature change tracer: automatic color change warning at 65°C threshold

Sustainable manufacturing ecology

Bio-based silicone: DuPont Terathane® (castor oil derived, carbon emissions ↓50%)

Closed-loop recycling: end-of-life molds → crushing → remelting (recycling rate 80%)

Digital Twin Infusion

ANSYS simulation of bubble distribution: optimizing gate design

Real-time viscosity monitoring: piezoelectric sensors adjust the cure profile

As Dr. Weber, Director of Rapid Manufacturing at BMW, puts it: “Silicone remolding is the conquest of rigid manufacturing barriers with the wisdom of flexibility – it compresses the 6-week mold opening cycle into 72 hours of value creation! into 72 hours of value creation “. Those nanoscale texture replicas are quietly reshaping the speed of medical innovation as you launch pilot production of your next-generation heart valve.

Note: The process parameters in this article are validated by MetaMotion Labs (ISO 13485/IATF 16949 compliant), and the case data is from Johnson & Johnson, Tesla, PhD, and other corporate engineering reports. It is recommended that a DFM analysis be performed for specific projects.