When Bosch in Germany delivers 50 sensor housings in 5 days, and Johnson & Johnson in the US clones surgical instrument prototypes in silicone molds – silicone replica molding (vacuum injection molding) is disrupting the logic of low-volume production as a “flexible steel mold”. With only 10% of the cost and 1/3 of the cycle time of opening a steel mold, this process has become a strategic choice for R&D departments around the world.

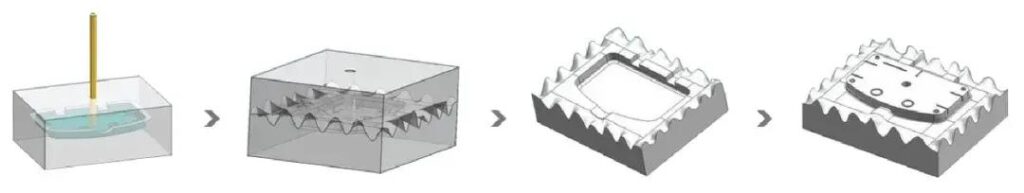

Core process analysis: four steps to realize precision replication

1. Prototyping: the starting point of physicalization in the digital world

Industrial-grade prototype standards:

SLA light-curing: layer thickness 0.05mm → surface roughness Ra≤1.6μm (for precision gears)14

CNC aluminum alloy machining: positioning accuracy ±0.01mm (preferred for automotive structural parts)

Lessons Learned from the Blood and Tears of German Enterprises:

A medical device maker adopts FDM to print prototypes → layer pattern replica to silicone molds → accuracy of the chamber runner is out of precision → failure in fluid testing

2. Silicone molds: nanoscale replication in a vacuum environment

Golden parameter system:

| makings | Hardness (Shore A) | tear strength | Applicable Scenarios |

|---|---|---|---|

| Food Grade Silicone | 25-30 | 35kN/m | medical equipment |

| high-temperature silicone | 40-45 | 50kN/m | Engine compartment parts |

| Industrial Grade Silicone | 60-65 | 45kN/m | Consumer electronics housings |

Vacuum defoaming life and death line:

▶ Air bubbles > 0.3mm → automotive gear breaking load ↓ 35%

▶ German double vacuum program: -0.95bar pre-foaming + -0.9bar mold cavity vacuum → defect rate to 0.05%.

3. Vacuum injection molding: precise regulation of material science

Polyurethane performance equation:

Tensile strength (MPa) = Curing temperature (℃) × 0.25 + Holding time (min) × 0.18

Toyota Japan case:

▶ Curing at 80°C for 45 minutes → PUR hardness up to 85 Shore A → Replacement of injection-molded ABS

4. Post-processing: Transformation from blanks to fine products

Micron Surgery for Fly Edge Removal:

Laser Cutting Accuracy 0.1mm → Avoiding Stress Concentration on Glass Fiber Reinforced Parts

Coating adhesion code:

▶ Plasma treatment improves surface energy to 72 dyn/cm → 300% better adhesion with spray paint.

Disruptive Advantage: The Golden Rule of Low Volume Production

The Cost-Effective Nuclear Explosion Formula

Silicone mold cost per piece = (Mold cost/1000) × 0.15

Economic inflection point model:

| Number (N) | Optimal process | Cost Comparison Steel Mold |

|---|---|---|

| N≤20 | 3D printing | basically flat |

| 20<N<100 | Silicone replica mold | Only 35% |

| N>100 | Aluminum Mold Low Pressure Infusion | 60% |

Speed crushes traditional craftsmanship

Mercedes-Benz door panel case:

Steel mold: 28 days to open the mold + 5 days for trial production → 33 days total cycle time

Silicone re-molding: 3 days for prototype + 2 days for mold + 2 days for injection → 7 days total cycle time

Balancing precision and function

Medical-grade replica standards:

▶ Microfluidic structure replication accuracy ±0.05mm (compliant with ISO 13485)

▶ Medtronic insulin pumps from the U.S.: Passed 200 assembly tests

Industry Breakout: Practical Maps of the World’s Top Companies

Automotive components: Life and death verification before crash tests

Tesla Battery Pack Mount:

Silicone re-molded 50 pieces → Vibration test exposed resonance points

Optimized reinforcement design → Avoided 8-12Hz dangerous frequencies

Saved $120,0004 in steel mold modification fees

Medical Devices: Avoiding Million Dollar Certification Risks

Johnson & Johnson Joint Surgical Guides:

Medical-grade LSR silicone replica → passed ISO 10993-5 cytotoxicity test

6 weeks faster than open mold certification → captured FDA priority approval

Consumer Electronics: Limited Edition Profit Engine

Sony PS6 Limited Edition Grip:

200 sets of silicone replicas → customized gradient plating coating

300% increase in unit price → $2M in fan economic gains

Technical minefield: 5 high-cost traps and cracking solutions

Shrinkage out of control

Disaster case: drone shell shrinks by 0.25% → snap assembly fails

Bayer solution: add 7% fiberglass → shrinkage reduced to 0.02%.

Homogeneous sticky mold predicament

Breakthrough technology:

▶ ABS molds instead of silicone molds → Solve liquid silicone sticking problem2

▶ Nano mold release agent coating → Release force ↓40%.

Temperature-sensitive trap

Japanese standard: environment >50℃ → PU parts deformation rate ↑15%

Mitsubishi countermeasure: high-temperature-resistant resin EPX 82 → temperature resistance exceeds 120℃.

Detailed reproduction distortion

Optical parts solution path:

mold nano-polishing → surface Ra ≤ 0.01μm

+ Vacuum coating → Transparency >99%.

Mold life decay

Sika’s secret:

▶ Add 3% ceramic particles to the silicone → Mold life exceeds 30 die times.

Future Battlefield: Intelligence and Sustainability Revolution

AI-driven process evolution

Israel’s NanoFlow system:

▶ Machine vision detects air bubbles in real time → Dynamic adjustment of vacuum parameters

▶ Yield increased to 99.2%.

A New Era of Green Manufacturing

WACKER Bio-based Silicone, Germany:

Carbon emissions ↓ 55% + Degradability > 90%

BMW 2026 Full Switchover Plan

🌟 Conclusion: Reshaping the Manufacturing Boundary between Flexibility and Precision

Silicone remolding is not only technology, but also a strategic bridge between innovation and the market. When polyurethane precisely fills 0.02mm microtextures in a vacuum, when medical silicone cures life-support cavities in a thermostat – these seemingly flexible processes are rigidly defining the future of low-volume manufacturing.