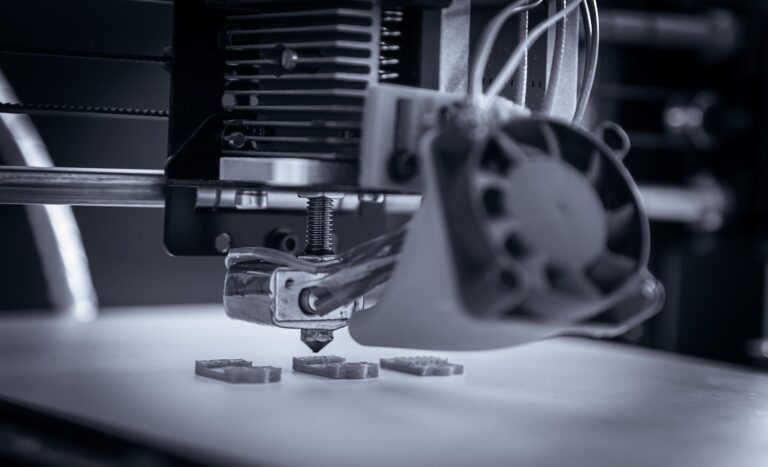

Driven by both global competition and smart manufacturing upgrades, Rapid Tooling has become a core gas pedal in the product development process. Compared with the traditional mold manufacturing cycle of months or even years, Rapid Tooling has completely reshaped the manufacturing logic from prototype validation to small batch production by virtue of its 7-15 days of speedy delivery capability and the core advantage of cost reduction of more than 35%.35 MetaMotion combines 18 years of experience in Rapid Prototyping and Rapid Tooling to provide you with an in-depth analysis of the revolutionary applications of Rapid Tooling technology in nine major fields. Mold technology in nine areas of revolutionary applications.

🚀 I. product development: from design iteration to functional verification of the “acceleration engine”.

Pain point: Traditional CNC machining or steel mold injection molding can’t meet the demand of high-frequency design iteration, resulting in long development cycles and high trial-and-error costs.

Technical Solution:

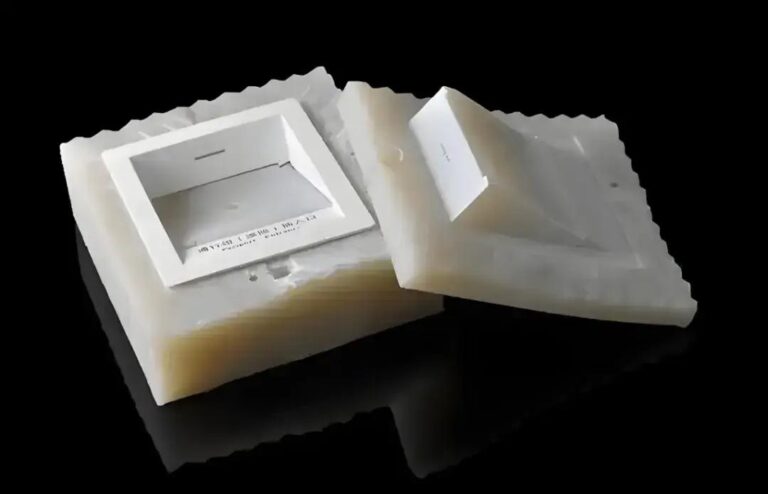

Arc Spraying Rapid Mold Making: Based on RP prototype spraying zinc-aluminum alloy shell, combined with epoxy resin backing, the flowerpot base injection mold is completed within 60 hours, and the cost is only 25% of the traditional method.

Silicone re-molding vacuum casting: Suitable for small batch of 50-500 pieces, realizing trial production of multi-material (ABS/PC/TPU) parts, with surface accuracy up to ±0.15mm/100mm, and supporting post-processing such as paint spraying and electroplating.

Case: SolisMed, a Swiss medical device manufacturer, used MetaMotion silicone re-molding solution to complete 3 generations of monitor shell iterations in 2 weeks, and passed the clinical test access 6 weeks ahead of schedule.

🚗 II. automobile manufacturing: the “cost-cutting tool” for the trial production of cover parts and mass production of interior trim.

Industry demand: prototype car trial production needs to take into account the high precision and low cost, the traditional steel mold single set of cost over a million, only applicable to the mass production stage.

Technological breakthrough:

Metal Arc Spraying Large Covering Part Molds: Xi’an Jiaotong University’s technology transformation case shows that this technology reduces the cost of molds to 10% of CNC machining, shortens the cycle time to 1/5, and has been successfully applied in the trial production of wing panels for AM08 model of Waveguide Automobile, and the life of the stamped parts reaches more than 500 pieces.

High melting point melting technology (such as the University of Tokyo RHST): stainless steel melting + metal backing reinforcement, to achieve mass production of instrument panel molds with leather texture, durability of more than 200,000 pieces.

⚡ III.Home Appliances and Consumer Electronics: “Dual Track Channel” for Functional Verification and Market Testing

Typical scenarios: smart home shell structure testing, heat dissipation component assembly verification, limited edition appearance parts production.

Technology Practice:

Reaction Injection Molding (RIM) molds: Metal sprayed zinc alloy molds support polyurethane material molding for the manufacture of thermostat panels for the U.S. smart home brand NexusHome, achieving 1,000-piece small batch production with no fusion marks on the surface.

Rapid Cooling and Hot Changing Mold Temperature (RHCM) Technology: AODE Machinery’s fourth-generation technology is used with rapid molds to solve the problem of flow marks on the surface of carbon fiber bicycle frames, with a 40% cycle time reduction.

✈️ IV. Aerospace: The “Lightweight Pusher” for Special Component Manufacturing

Core Challenge: Complex geometric parts such as impellers and turbine blades are difficult to process traditionally, and material costs are extremely high.

Innovative solutions:

Direct laser melting (LMF): Sandia National Laboratories using layer-by-layer metallurgical bonding process, manufacturing density of 90% of the nickel-based alloy engine components, mechanical properties close to the forging 7.

Molten tungsten carbide molds: for high-temperature resin-based composites (eg, PEKK) molding to meet the fire safety standards of the aircraft interior parts, mold life of more than 3,000 pieces.

🏥 V. Medical devices: customization and compliance “double standard” of the guarantee

Rigid demand: implantable devices need to match the patient’s anatomical structure, and need to comply with ISO 13485 certification system.

Technology landing:

3D printing + silicone re-molding dual-track system: based on the patient’s CT data to print SLA skull models, turning biocompatible silicone molds, batch casting of titanium alloy custom implants.

Micro-arc spraying: manufacturing molds for minimally invasive surgical forceps with multi-joint connectors, one-piece molding to avoid loss of strength in piecemeal assembly, accuracy ±0.05mm.

🏺 VI. cultural relics protection: non-contact replication of the “space-time bridge”

Technology highlights:

Three-dimensional scanning + SLS prototype flip mold: non-contact scanning of fragile cultural relics (such as bronzes), printing resin prototypes after arc spraying zinc alloy, to achieve non-destructive replication, surface decoration restoration degree of 98%.

🔬 VII. Research and Market Testing: “Decision Building Blocks” for Low-Cost Validation

Core value:

User feedback drives design: MetaMotion manufactured 500 sets of fitness tracker housings for German sports brand AdvaFit and put them into the European market for testing, collecting data to optimize the design of injection molding ports within 2 weeks to avoid loss of rework of mass production molds.

⚙️ Technical Advantages and Selection Guide

| norm | Silicone replica mold | Metal Arc Spraying | High melting point fusion injection |

|---|---|---|---|

| Typical Life | 50-500 pieces | Stamped parts 500+ | Injection molded parts 200,000+ |

| Surface Accuracy | ±0.15mm/100mm | ±0.1% dimensional distortion | Ra 1.6μm |

| Cost savings rate | 60% vs. steel mold | 70% vs. CNC | 50% vs. conventional fusion injection |

| Best Scene | Multi-material and small batch | Large Coverings | Textured interior trim |

Data source: Xi’an Jiaotong University Technology Transformation Case 3, Nissan Application Report

💎 Conclusion: Rapid Tooling – A Strategic Pivot to Connect Innovation and Markets

From “quick prototyping” to “small batch production”, Rapid Prototyping has broken through the shackles of traditional manufacturing, and MetaMotion’s industry practice has shown that in the three major high-value sectors of medical, aerospace, and automotive, the use of hybrid processes (e.g., RP + arc spraying) can further reduce cycle costs by 30%69. MetaMotion’s industry practice shows that in the three high-value sectors of medical, aerospace and automotive, hybrid processes (e.g. RP + EArc Spraying) can further reduce cycle time costs by up to 30%.69 Rapid Prototyping is not an option when your projects are challenged with “low volume, high time-to-market, and frequent changes” – it’s the first ace in the hole in your manufacturing strategy.

Unlocking design freedom starts with the right process choice, and MetaMotion’s 18 years of rapid prototyping technology provides you with an end-to-end solution from prototype to 5,000-piece volume production – so innovation doesn’t have to wait.