In the rapid development and validation phase, the Silicone Rubber Prototype has become an important tool for many companies to evaluate the actual performance of rubber parts, rubber-coated parts or flexible connecting parts due to its excellent flexibility and realistic tactile simulation ability. Compared with the traditional rigid board, the soft rubber board can more realistically reflect the use of flexible parts, and effectively improve the efficiency of product design and user experience.

First, the core process: silicone re-molding technology to achieve a high degree of reproduction

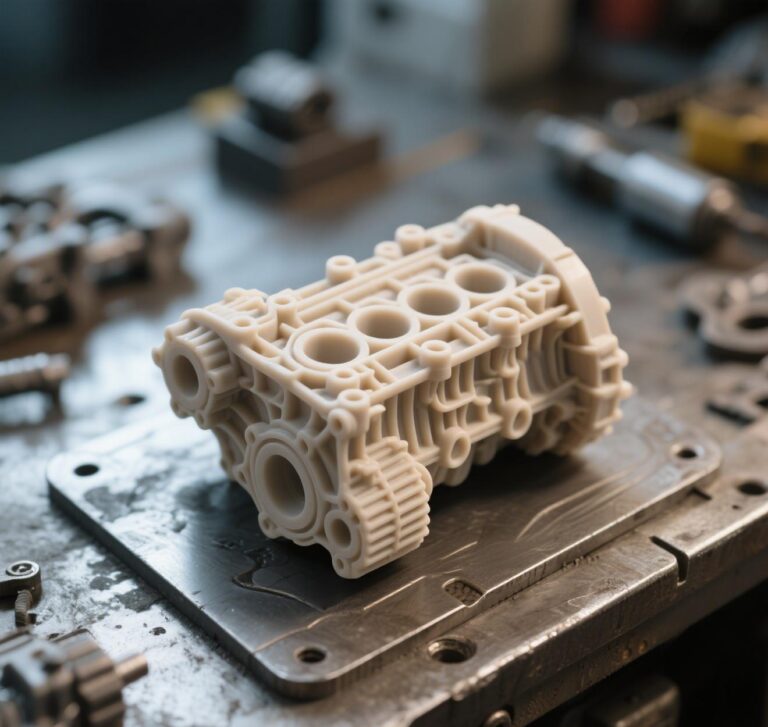

The core of soft plastic hand plate production is silicone mold reproduction technology (Silicone Molding), the process is efficient and high degree of reduction:

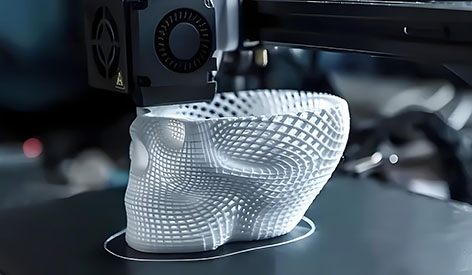

Master mold production: first of all through 3D printing or CNC machining to produce an accurate original model (master mold).

Silicone Molding: Liquid Silicone Rubber is poured around the master mold and cured to form a flexible silicone mold with high detail reproduction capabilities.

Material remolding: Injecting flexible materials into the silicone mold, such as PU, TPU, silicone rubber or TPE, etc. After curing, the mold is removed to obtain the final soft plastic handpiece.

This process is especially suitable for a small amount of trial production and form verification stage, can quickly obtain and final product touch and physical properties of the sample is highly close to accelerate the project process.

Second, the material and process characteristics: to meet the needs of diversified flexibility verification

The core of the performance of the soft plastic board lies in the material selection and fine process control:

Key flexible materials:

PU soft rubber: wide range of hardness, good abrasion resistance, moderate cost.

Silicone Rubber: High biocompatibility (commonly used in medical devices), high and low temperature resistance, excellent elasticity, optional transparency.

TPU (Thermoplastic Polyurethane): High strength, outstanding abrasion resistance, oil resistance, commonly used in adhesive-covered parts, wearable devices.

TPE (thermoplastic elastomer): easy to process, recyclable, various handfeel.

Selection basis: according to the product on the softness, elasticity, strength, temperature resistance, chemical resistance, transparency and biocompatibility (such as medical device shell) of the specific requirements to choose the most appropriate material.

Process Points:

Mold Design: Ensure smooth demolding and avoid damaging the soft rubber parts. The flow of the material is taken into account.

Vacuum degassing: Vacuum degassing before and after pouring is essential to eliminate air bubbles, ensure internal densification and surface quality, and prevent shrinkage.

Surface and feel customization: Rich colors can be achieved by mixing pastes. Adding specific additives can simulate the feel of real products, such as increasing anti-slip or precisely adjusting the softness.

Third, the core application areas: close to the real scene of the flexible verification

Due to its excellent flexibility, tactile realism and assembly adaptability testing capability, the soft rubber hand panel has become an ideal tool for verifying flexible design concepts and is widely used in:

Medical device housings and components: Verification of human contact comfort, sealing and biocompatibility requirements.

Consumer electronics protective components: such as cell phone cases, headphone covers, waterproof seals, etc., to test protection, tactile sensation and assembly.

Automotive gaskets: Verification of sealing performance, weatherability and assembly fit.

Silicone structures for wearable devices: e.g. watch bands, health monitoring components, to test wearing comfort, elasticity and durability.

Overmolded parts development: Especially critical! Softgel boards can be used to test in advance the structural stability of the softgel covering position and the combination of internal hard parts, significantly reducing the risk and cost of rework due to design problems after formal molding.

Conclusion: Unleash the potential of softgel boards in product innovation!

As an indispensable part of the verification of flexible parts, the softgel board provides highly reproducible tactile feedback and performance data for the design scheme, which is a reliable basis for product optimization and user experience testing. Through accurate material selection, fine process control (especially vacuum degassing and mold design) and clear validation objectives, companies can maximize the value of softgel templates in the product development process. As the market demand for customization and functional integration continues to rise, softgel template technology will show its unique advantages in a wider range of innovation scenarios.