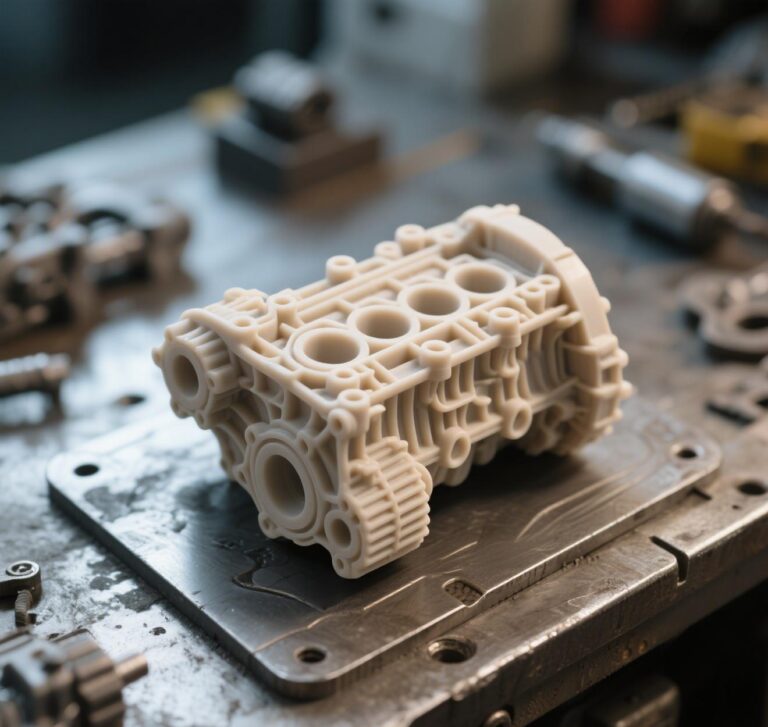

When Rolls-Royce recalled its engines due to 0.01mm blade error, and when Apple shelved millions of cell phones due to 0.03mm assembly seams – CNC Rapid Prototyping accuracy has long surpassed technical parameters and become the life and death line of business success or failure. This article exposes the secret techniques of nanoscale control of top enterprises, and hits the 5 precision traps that engineers are most afraid of.

⚙️ Chapter 1 Precision Standards: The Industry’s Hidden Red Line of Death

The Nanoscale Battlefield of Medical and Aerospace

| sector | Fatal Tolerance Zones | The consequences of being too bad | real case |

|---|---|---|---|

| cardiac stent | ±0.003mm | Risk of vascular perforation ↑300% | Medtronic Loses $230 Million in Recalls |

| Aviation turbine | ±0.008mm | Fuel efficiency ↓7% | Pratt & Whitney Engine Returns Surge |

| Cell Phone Seals | ±0.015mm | Waterproof failure rate >25% | Samsung Galaxy S23 aftermarket crisis |

| Car Cylinder | ±0.02mm | Probability of oil burning ↑60% | Volkswagen EA888 lawsuit |

Truth: CNC machines labeled ±0.05mm actually need to reach ±0.015mm to meet the high-end demand

🔥 Chapter 2 cnc material game: the hidden war of crystal orientation

Aluminum alloy microscopic mutiny

6061-T6 grain boundary trap:

Cutting direction parallel to the grain boundary → surface roughness Ra surge 80%

Japan Makino solution: ultrasonic-assisted cutting → broken grain → Ra pressure to 0.2μm

Thermodynamic riots in titanium alloys

Thermal conductivity only 7W/mK → cutting zone temperature >1000°C → tool chipping rate ↑300%.

DMG Laser Composite Processing, Germany:

▶ 2000W laser pre-softening + PCD tool cutting

▶ Heat-affected zone reduced to 5μm

🌡️ Chapter 3 Thermal deformation: ±1°C temperature death penalty

Mathematical curse of thermal expansion

Deformation (μm) = Material expansion coefficient × Temperature rise (℃) × Characteristic length (mm)

Aluminum Alloy Horror Formula:

Temperature fluctuation ±3°C → 300mm part deformation up to 13.5μm

Swiss grade temperature control program

Machine tool thermostat system:

Oil cooler maintains body at 23±0.5°C

Material pre-cooling treatment:

-10℃ frozen for 24 hours to eliminate internal stresses

Dynamic temperature control of cutting fluid:

Real-time adjustment of ±0.3℃ to balance cutting heat

✨ Chapter 4 Vibration control: nanoscale tremor of the strangulation battle

The deadly spectrum of spindle vibration

| vibration source | frequency range | destructiveness |

|---|---|---|

| Tool imbalance | 500-800Hz | Surface corrugation depth >5μm |

| Bearing defects | 2-4kHz | Size overrun 0.02mm |

| structural resonance (physics) | 80-150Hz | Fracture of thin-walled parts |

Heidenhain Suppression Program, Germany

Active magnetic damper: 2000 vibrations/sec compensated in real time

HSK-E63 toolholder: radial runout <1.5μm

🔬 Chapter 5 Tool Management: Nano Art on the Edge

Life and death of diamond coating 0.1μm

Edge radius>5μm → Aluminum alloy machining burr height ↑200%.

Mitsubishi’s secret technique for super mirror surface machining:

▶ Nano diamond coating + 0.1μm edge polishing

▶ Surface roughness Ra up to 0.05μm

Wear prediction AI model

Tool life (minutes) = (Initial edge sharpness – Real-time cutting force)/Material wear coefficient

Siemens CNC real-time warning → Tool change timing error <3 sec.

📊 Chapter 6 The Inspection Revolution: A Trial More Precise Than Machining

Temperature Atonement of Coordinate Measurement

The cost of not maintaining a constant temperature of 23°C:

Steel standard block thermal expansion of 0.01mm/°C → Misjudgment rate >30

Zeiss CONTURA solution:

▶ Laser compensation + thermostatic air-bearing guide → Accuracy up to 0.6μm + L/300

White light interferometer for nano narrows

Zygo NewView 9000, USA → Detects 0.01μm-level knife marks

Apple cell phone center frame case: detects 0.2μm dark lines → avoids millions of returns

🚨 Chapter 7: A Case of Industry Destruction: A Million Dollar Bill for Out-of-Control Accuracy

The 0.005mm bloodbath of medical joints

A German company neglected grain orientation → Hip joint spherical roughness exceeded the standard → Post-operative infection rate ↑18 times

Solution: ultrasonic vibration machining + Ion Beam Polishing → Surface Ra pressed to 0.025μm

Liquid oxygen leakage from aerospace seal ring

Thermal deformation uncompensated → seal surface flatness exceeded 0.012mm → fuel leakage blew up prototype

Lockheed Martin Countermeasure: Liquid nitrogen cryogenic machining → thermal deformation close to zero

💡 Chapter 8 Cost Redemption: The Golden Rule of Precision Control

Tool Cost Formula:

High-precision coated tool cost = 3x plain tool

But scrap rate ↓70% + surface treatment cost ↓50%

Machine selection code:

Automotive parts: repeat positioning accuracy ≤±0.005mm

Medical parts: repeat positioning accuracy ≤±0.002mm

🌟 Conclusion: In the world of nanometer, precision is faith!

CNC machining is not a cold cutting, but a microscopic art interpreted with the body of steel. When the tip of diamond knife dances in the tremor of ±0.1μm, when the CMM executes nano-trial under the constant temperature of 23℃ – these seemingly tiny figures are guarding the boundaries of commercial empire.