CNC (Computer Numerical Control) machining is an efficient and precise machining technology widely used in modern manufacturing industry.

Machining accuracy is one of the important indicators to assess the quality of CNC machining, which directly affects the performance and life of the final product.

01.Definition of CNC machining accuracy

CNC machining accuracy refers to the degree of conformity between the actual size, shape, position, etc. of the machined part and the design requirements. It mainly includes the following kinds of precision:

① Dimensional accuracy

Dimensional accuracy refers to the deviation between the actual size of the machined part and the design size. Commonly used tolerance band (Tolerance) to indicate that the smaller the tolerance band, the higher the dimensional accuracy.

② Shape accuracy

Shape accuracy refers to the deviation between the actual shape of the machined part and the designed shape, including roundness, flatness, straightness and so on. The smaller the shape error, the higher the shape accuracy.

③ Positional accuracy

Positional accuracy refers to the deviation between the actual position of the machined part and the designed position, including coaxiality, symmetry, parallelism and so on. The smaller the positional error, the higher the positional accuracy.

02.Factors affecting CNC machining accuracy

CNC machining accuracy is affected by a variety of factors, mainly including the following aspects:

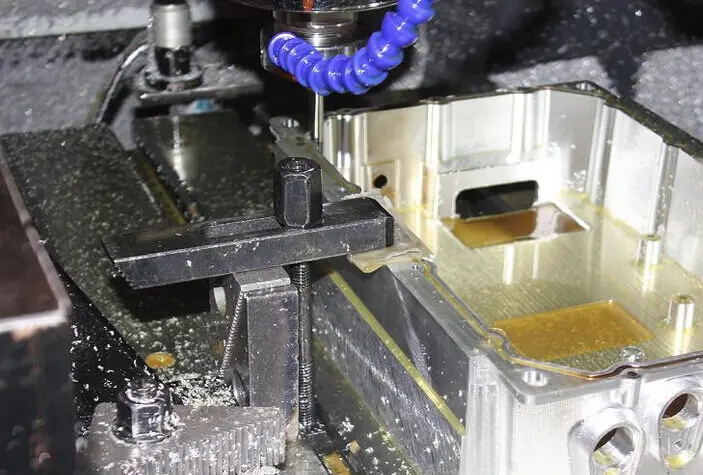

① Machine tool precision

The manufacturing accuracy and rigidity of the machine itself has a direct impact on machining accuracy. High precision, high rigidity of the machine tool can better resist the vibration and deformation generated during the machining process, thereby improving

③ Clamping accuracy

The positioning accuracy and clamping force of the fixture also have an effect on the machining accuracy. Accurate positioning and stable clamping can reduce the movement and deformation of the workpiece during machining.

④ Machining parameters

Machining parameters such as cutting speed, feed and depth of cut have a direct impact on machining accuracy. Reasonable machining parameters can reduce thermal deformation and vibration during machining and improve machining accuracy.

03.Methods to improve CNC machining accuracy

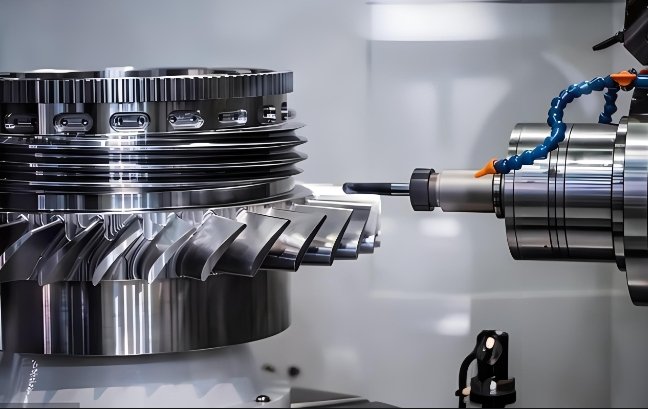

① Selection of high-precision machine tools

The selection of high-precision, high-rigidity CNC machine tools is the basis for improving machining accuracy. High-quality machine tools provide a more stable machining environment and reduce machining errors.

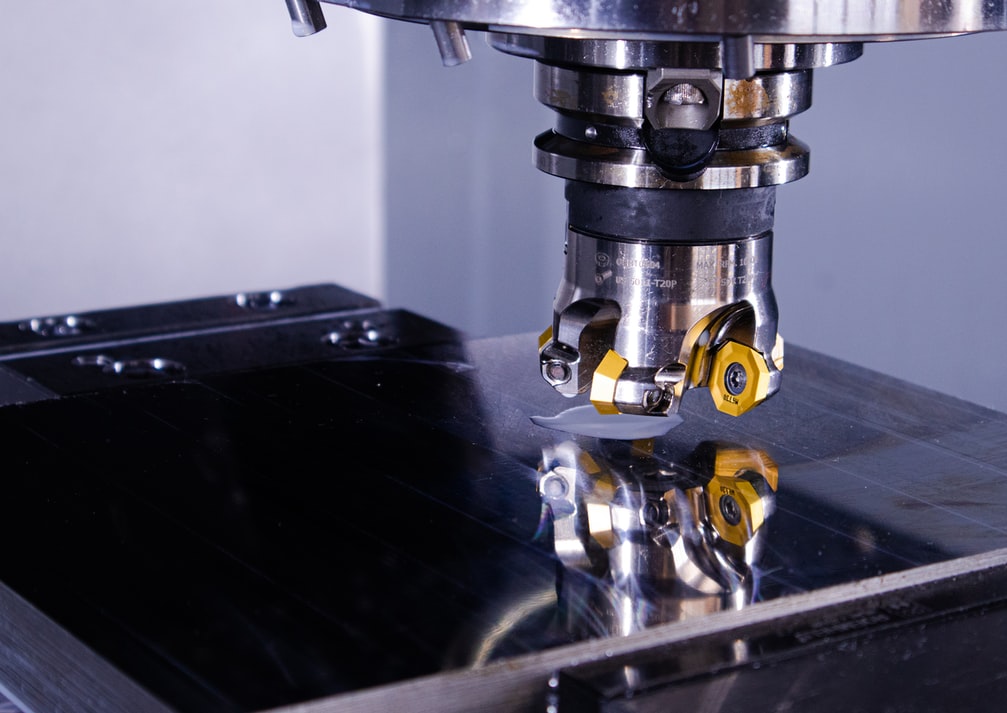

② Use of high-precision tools

Select high-precision, wear-resistant tools, and regular tool inspection and replacement to ensure the geometric accuracy and cutting performance of the tool.

③ Optimize fixture design

Design and use high-precision fixtures to ensure the stability and accurate positioning of the workpiece in the machining process. Avoid fixture deformation and workpiece loosening to reduce machining error.

④ Reasonable setting of machining parameters

According to the material characteristics and machining requirements, reasonably set the machining parameters such as cutting speed, feed and depth of cut to reduce the thermal deformation and vibration generated in the machining process.

⑤ Control the machining environment

Conduct machining in a constant temperature environment to avoid temperature fluctuations on the machine tool and workpiece. If necessary, methods such as coolant and air cooling can be used to control the machining temperature.

⑥ Online detection and feedback

Adopting online detection and feedback system, real-time monitoring of size and shape errors in the machining process, timely compensation and adjustment to improve machining accuracy.

04. Practical application of CNC machining accuracy

CNC machining accuracy has important applications in many demanding fields:

① Aerospace

The aerospace field requires extremely high precision in the size and shape of parts. High precision CNC machining can ensure the performance and safety of aircraft, satellite and spacecraft components.

② Medical Devices

Medical devices such as artificial joints, implants and surgical instruments require high machining accuracy. CNC machining can provide high precision and high surface quality medical device parts to ensure their safety and reliability.

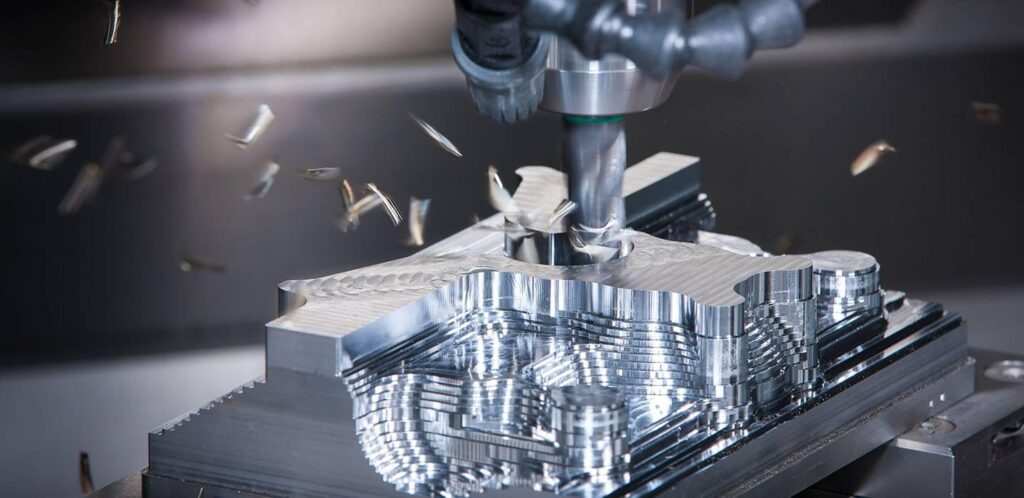

③ Mold Manufacturing

Mold manufacturing requires high precision and surface finish to ensure consistent product quality, and CNC machining can accurately machine molds with complex shapes and microstructures to improve the service life of the molds and the quality of the products.

⑥ Online detection and feedback

Adopting online detection and feedback system, real-time monitoring of size and shape errors in the machining process, timely compensation and adjustment to improve machining accuracy.

04. Practical application of CNC machining accuracy

CNC machining accuracy has important applications in many demanding fields:

① Aerospace

The aerospace field requires extremely high precision in the size and shape of parts. High precision CNC machining can ensure the performance and safety of aircraft, satellite and spacecraft components.

② Medical Devices

Medical devices such as artificial joints, implants and surgical instruments require high machining accuracy. CNC machining can provide high precision and high surface quality medical device parts to ensure their safety and reliability.

③ Mold Manufacturing

Mold manufacturing requires high precision and surface finish to ensure consistent product quality, and CNC machining can accurately machine molds with complex shapes and microstructures to improve the service life of the molds and the quality of the products.