Case Details

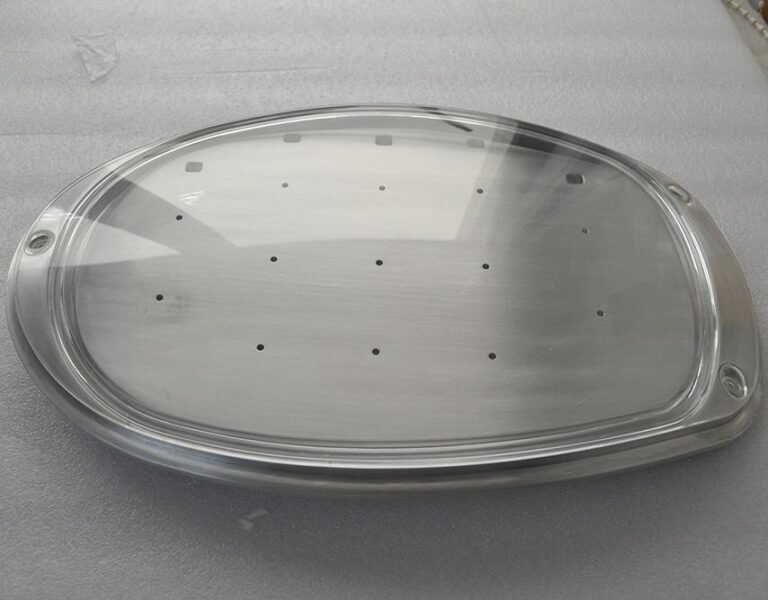

Name: Rapid prototyping of bicycle parts

Industry/Classification: Other

Processing method: Low pressure infusion

Material used: Aluminum alloy

Maximum precision: 0.05mm

Production cycle: 2~3 days

Product size: 10cm*13cm*11cm

Post-processing: Sandblasting

Case Introduction

Rapid prototyping of bicycle functional parts is a specialized process, which involves many aspects such as appearance design, structural verification and functional testing. Here are some key points:

rapid prototyping types: According to the requirements, rapid prototyping can be categorized into appearance rapid prototyping, structural rapid prototyping and functional rapid prototyping. For bicycle functional parts, it is usually necessary to combine these types to ensure that the product can meet the design requirements. For functional bicycle parts, it is usually necessary to combine these types to ensure that the product’s appearance, structure and function meet the design requirements.

Material selection: Most bicycle parts are made from aluminum alloys because they are lightweight and strong. In rapid prototyping, choosing the right material is critical to ensuring the quality of the product.

CNC machining: CNC (Computer Numerical Control) machining is a common method of making precision hardware for rapid prototyping. It provides high precision and a smooth surface finish, making it ideal for functional bicycle parts.CNC machining can handle a wide range of materials, including metal and plastic parts.

Quality control: Quality control is very important in rapid prototyping. Processing plants need to have strict quality control measures in place to ensure product stability and reliability. This has a direct impact on the subsequent mass production and product quality.

Functional test: Through the functional test of the handpiece, the defects and problems of the product can be found in time, so as to improve the quality and stability of the product. rapid prototyping can also be used as a reference sample for mass production, which can help the manufacturer to understand the requirements of the product and the processing flow accurately.

Technology maturity: CNC technology is widely used in the machining industry and is relatively mature, making it one of the preferred methods in rapid prototyping. It can provide good results and accuracy, although the cost may be higher.

Customized machining: Due to the wide variety of rapid prototyping designs and fabrications, it requires flexibility and variety in the machining capabilities of machinists. It is very important to be able to customize the processing according to the requirements of different products.

To summarize, rapid prototyping of bicycle functional parts is a comprehensive process, which needs to consider many factors such as design, material, processing technology and quality control. Through professional rapid prototyping, the quality and market competitiveness of products can be effectively improved. When choosing a rapid prototyping factory, be sure to consider whether they have the relevant technology and experience to ensure the quality and effectiveness of the final product.