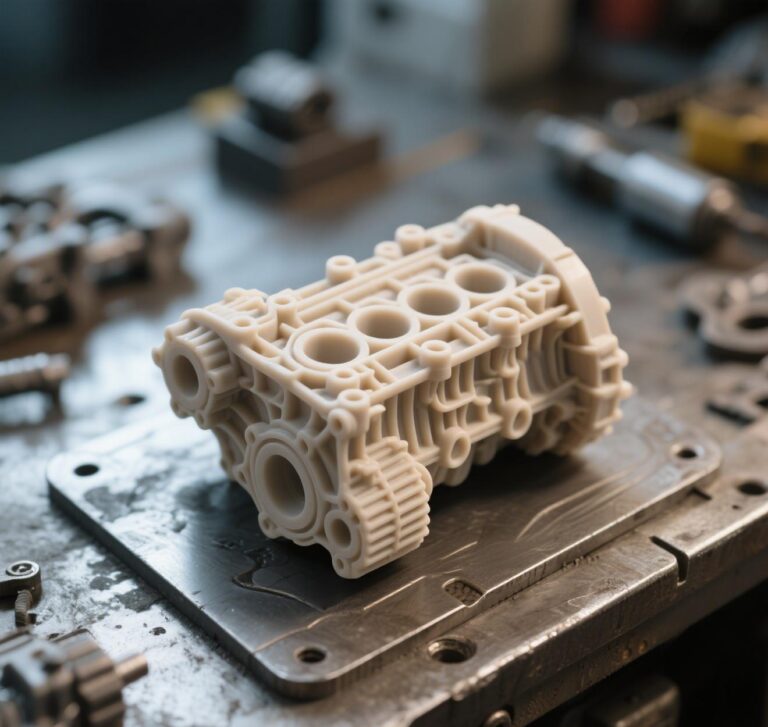

In the world of high-precision rapid prototyping, CNC programming is like the baton of a symphony orchestra – the slightest deviation can cause the entire performance to collapse. Even in today’s booming 3D printing technology, experienced CNC programming engineers are still the core drivers of prototype quality and delivery.

MetaMotion combines 18 years of experience in 5-axis linkage machining to reveal the 9 key issues in CNC rapid prototyping programming that top programmers in the industry will never ignore, helping you to avoid the millions of dollars in trial and error costs.

⚙️ I. Process Prejudgment: Full chain projection from disassembly strategy to post-processing

Fatal error case:

VitaMed, a U.S. medical device manufacturer, once split a titanium monitor housing into 3 pieces for CNC machining because the programmer ignored the water plating process requirements. After assembly, the plating solution penetrated at the seams, resulting in 300 prototypes being scrapped and a direct loss of $150K.

MetaMotion Solution:

1. Deep optimization of disassembly logic

Plating parts: water plating requires mandatory one-piece molding strategy (e.g., 5-axis positioning machining), vacuum plating can be split but need to leave 0.3mm gluing margins

Transparent parts: prefer PMMA to PC to avoid tool marks showing up in the polished surface.

2. Tool-material matching matrix

| Material type | Recommended number of blades | Coating technology | Linear speed (m/min) |

|---|---|---|---|

| ABS/PC | 2-flute aluminum milling cutter | TiAlN | 220-280 |

| 6061aluminum | 3-flute corrugated milling cutter | Diamond-Like | 350-420 |

| SUS304 stainless steel | 4-blade carbide | AlCrN | 80-120 |

Source: Sandvik Guide to Cutting Difficult Materials

II. The software selection: Mastercam and UG of the actual game (core keywords: five-axis toolpath optimization)

Industry truth:

Mastercam 2024: 40% increase in efficiency in 3+2 fixed-axis machining (especially suitable for multi-cavity medical parts)

UG NX 2306: 35% reduction in machining time for impeller-type parts in continuous 5-axis linkage scenarios

Lessons from German auto parts dealer AutoTech:

Programming a turbine prototype with Mastercam 9.1 resulted in $80,000 in spindle damage on a German DMG machine due to the software’s inability to calculate collision avoidance at the root of the blade.

🛠️ III. Machine Characteristics: The “Invisible Pitfalls” of 5-Axis Equipment

Parameters that must be verified:

1. RTCP function enabled status:

Mazak VARIAXIS i-800 C-axis positioning error up to 0.02mm at ±110°

2. Thermal deformation compensation table:

For every 1°C rise in ambient temperature in the Swiss GF Machining solution, the Z-axis needs to be compensated for 0.007mm.

IV. Tool path planning: thin-walled parts processing “life and death line”

Aerospace parts combat cases:

Problem: 0.8mm thick titanium alloy wing in the traditional isometric machining vibration knife rupture

Program:

- G187 P3 E0.05 ; Mazak Smooth High Precision Mode

- #1=0.2 ; Initial depth of cut

- WHILE[#1LE5]DO1

- G1 Z-#1 F800

- G41 D22 X30 ; Radial cut width only 0.15mm

- #1=#1+0.05

- END1

Vibration amplitude reduced by 76%, surface roughness Ra≤0.8μm

🔬 V. Simulation verification: avoiding physical collisions with “digital twins”

The 3 major dead zones that must be checked:

1. Toolholder-fixture interference: especially when using Kennametal Hydra-Cool long-neck toolholders.

2. Workpiece-turntable collisions: singularity problems with 5-axis tilts over 45°

3.Cutting force overload: aerospace alloy machining needs to monitor axial forces >200kgf

VI. Efficiency Revolution: Tool Life and Cost Balancing Technique

Optimal cutting parameter calculation model:

VT^n = C → Upgrade to

[V×(DOC^0.78)×(WOC^0.22)] / [T^(0.28)×(HRC/50)^1.6] = K

Among them:

V=cutting speed (m/min)

DOC=depth of cut (mm)

WOC=step (mm)

T=target life (min)

HRC=material hardness

K=material coefficient (Aluminum 6061: 480)

✨ VII. Millimeter-level persistence: 5 devilish details of precision control

1. margin allocation strategy:

Roughing leave 0.5mm (steel parts) / 0.3mm (aluminum parts)

semi-finishing leave 0.15mm

Finishing with a waveform tool path to eliminate joint marks

2. Thermal management program:

Aluminum alloy: compressed air temperature control at 16±2°C

Stainless steel: emulsion concentration is increased to 12

🚨 VIII. Safety red line: 3 life-saving regulations for 5-axis machining

- G43.4 and G43 switching taboo: Japan’s Makino machine tools in the G43.4 mode to disable the length of the compensation

- Rotary axis soft limit check: Germany’s Hammer C42 C-axis in the -185 ° to +185 ° will be triggered by the mechanical locking

- Emergency Stop Vector Direction: the workpiece weight > 50kg need to recalculate the moment of inertia

🔍 IX. Fieldism: The Programmer’s “Groundwork Practice”

When a 0.02mm profile deviation occurred in the impeller prototype of the German precision instrument manufacturer Precitec, Markus Schneider, Director of Programming, found it while crouching on the shop floor for six hours:

Spindle nose temperature had risen to 41.3°C (standard value ≤38°C)

Coolant concentration had dropped from 8% to 5.7%

Solution:

Add a 10-minute spindle cooling cycle prior to finishing and add a module for automatic concentration monitoring

💎 The Ultimate Advice: CNC Programming is a Science and an Art

In MetaMotion’s rapid prototyping system, a top programmer needs both:

Mathematician’s rigor (0.001mm paranoia)

Militant’s strategy (ability to deduce the whole process)

Craftsman’s intuition (listening to the cutting sound to recognize the state)

Every perfect prototype delivery starts with a crazy obsession for details.

MetaMotion’s 5-axis CNC rapid prototyping service combines German precision with Silicon Valley efficiency to help you turn your design into a verifiable physical entity – from concept to functional verification in as little as 48 hours.