When Tesla 3D prints brake caliper prototypes in 48 hours, and when Porsche captures 0.03mm assembly deviation in CNC micro-vibration – rapid prototyping has long gone beyond the realm of “prototyping” and has been elevated to the status of a strategic weapon for technical decision-making. This guide unites the practical experience of German, American and Japanese automobile enterprises, and hits the 9 traps that engineers suffer from the most.

🧩 Chapter 1: Design Preprocessing: Accurate Starting in the Digital World

List of “fatal details” of CAD files

Topology Optimization Pitfalls:

Internal overhangs not removed → CNC machining time for empty tools increased by 35%

Chamfers not parametrically associated → stress concentration risk increased dramatically after wall thickness change

GM Standard Solution:

▶ SolidWorks Design Tree to control feature associations

▶ Thin-walled parts mandatory addition of reinforcing bars (≥30% of thickness of the main body)

The Cost-Performance Game of Material Selection

| take | Materials of Choice | alternative | lesson learned through blood and tears |

|---|---|---|---|

| Interior Tactile Validation | ABS+TPU overmolding | Pure ABS with soft-touch paint | Nissan test: paint peeling in 3 months |

| Engine compartment heat-resistant parts | PA66+30%GF | Nylon | Volkswagen EA888 prototype heat distortion exceeds the limit by 2 times |

| Lampshade Optical Verification | Medical Grade PC | Ordinary PC | BMW LED headlight yellowing index ΔE=4.2 |

⚙️ Chapter 2: The Process Battlefield: Bayonets of Three Major Technologies

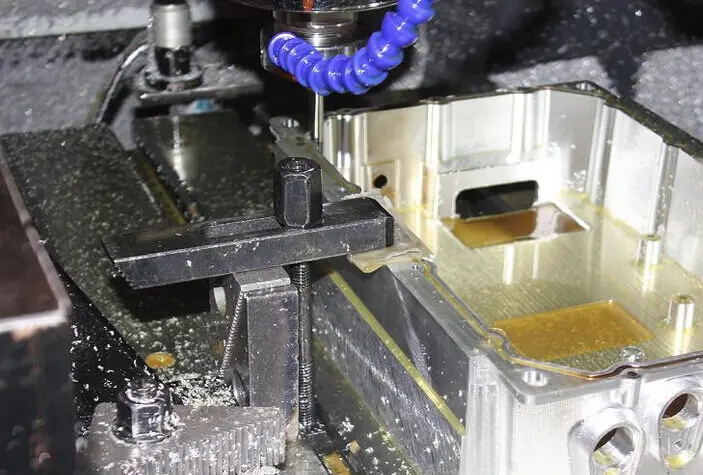

Five-axis CNC machining: micron-level vibration of the war of attack and defense

Tool vibration dark mine:

Radial runout>0.005mm → Thin-walled parts with dimensional overshoot up to 0.12mm

Makino Machine Tool Solution in Japan: HSK-E63 shank + active vibration damping → Vibration pressed down to within 1μm

Thermal deformation pre-compensation formula:

Aluminum alloy compensation = (cutting temperature -25℃) × 0.023mm/m

Steel compensation = (cutting temperature -25℃) × 0.011mm/m

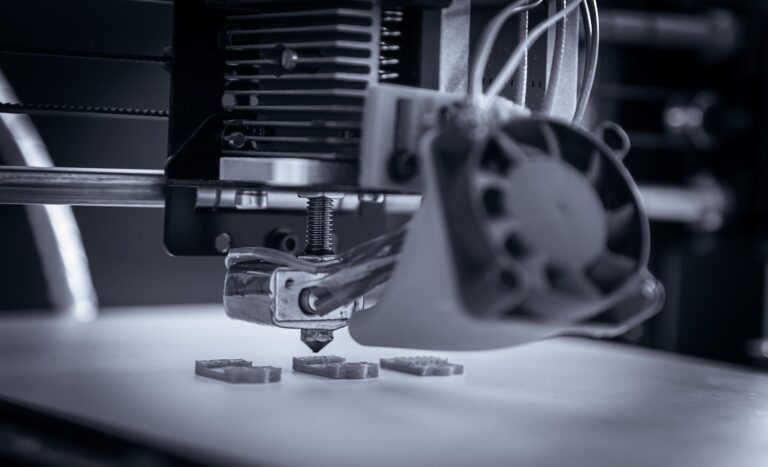

Industrial 3D Printing: The Sharp Edge that Pushes the Boundaries of Traditional Manufacturing

Innovations in Light Curing Technology:

EnvisionTEC Perfactory®, Germany → Layer thickness 0.025mm → Lamp texture clarity beyond injection molded part

Selective Laser Sintering Breaking Point:

BMW Intake Manifold Prototype: PA12 Powder → Temperature Resistance 130°C → Passed 100,000 Pulse Tests

Vacuum Casting: Cost Butcher for Small Volumes

18 chances for silicone molds:

ELASTOSIL® mold adhesive from WACKER, Germany → single mold output of 18 pieces with ±0.1mm accuracy

Mercedes-Benz door handle validation: only 7% of the cost of steel molds

Polyurethane black technology:

▶ BASF PUR 60-1000 series → Tensile strength > 60MPa → Impersonating injection molded ABS

✨ Chapter 3 Surface Treatment: The Art of Disguise at the Nanoscale

Environmental Breakthrough of Plating Process

Alternatives under the hexavalent chromium ban:

| skill | adhesion | cost factor | Application Cases |

|---|---|---|---|

| Trivalent Chromium Plating | ASTM 4B | 1.8X | Audi Signage |

| PVD Nano Plating | ASTM 5B | 2.5X | Porsche Exhaust Trim Pipe |

| Water plating ABS+UV | ASTM 3B | 0.9X | Toyota center buttons |

The devil’s details of the spraying process

Coating adhesion code:

Sanding roughness Ra 0.8-1.2μm → sweet spot for optimum adhesion

Q-Lab UV aging chamber: 1500 hours of testing ΔE < 1.5 to meet the standard

Triple-coating and triple-baking trap:

▶ Insufficient flash-drying of the layers → solvent retention → blistering of the coating after six months

🔧 Chapter 4: Functional Verification: The Last Escape Before Mass Production

NVH noise tracking guide

Bosch sensor array program:

20 microphones + accelerometer → locate >20dB rattle source

Ford door panel case: locate snap interference point → modify 0.3mm to avoid 10 million recalls

Environmental Simulation Extreme Test:

▶ -40℃ Cold Start Verification → Russian Lada Transmission Prototype Seal Cracking

A revolution in virtual assembly prognostics

Tolerance Stacking Simulation Software:

Siemens PLM VisVSA → Predicting 14th part assembly failure

Tesla Battery Pack Case: Correcting bracket holes ahead of time → Saving 28 days of rework cycle time

📦 Chapter 5 Logistics and Knowledge Management: the life and death of cross-continental collaboration

The Physics Equations of Shock-Proof Packaging

Resonance frequency annihilation:

No spectrum analysis → 5-200Hz random vibration → brittle parts fracture rate >30%

German SCHUTZ solution: EPP foam molding + vibration optimization → attenuation peak 12dB

Blockchain traceability system

Laser QR code etching:

6061-T6 parts are etched 0.05mm deep → alcohol wipe 100 times without falling off

Data uploading and depositing:

▶ Material lot number + processing parameters + inspection report → permanent tamper-proof

💡 Chapter 6: Three Nucleation Points for Cost Control

Process inflection point model:

When N < 50 → Prefer 3D printing

When 50 < N < 200 → Vacuum casting cost optimization

When N > 200 → CNC small batch processing is more economical

Material substitution formula:

Non-load bearing structure: glass fiber reinforced PP instead of PA66 → 40% cost reduction

Surface treatment trade-offs:

Internal parts: sandblasting instead of electroplating → $15 per piece savings

🌟 Conclusion: Dancing on a tightrope of speed and precision

The essence of rapid prototyping for automobiles is to use trial and error at a controlled cost for zero risk in mass production. When you correct the design in the micron-level vibration of the five-axis machine tool, and anticipate batch defects in the vacuum-injected silicone mold – these seemingly cold prototypes are reshaping the DNA of the future car.