Silicone molding/low pressure infusion

Silicone Remolding/Low Pressure Pouring

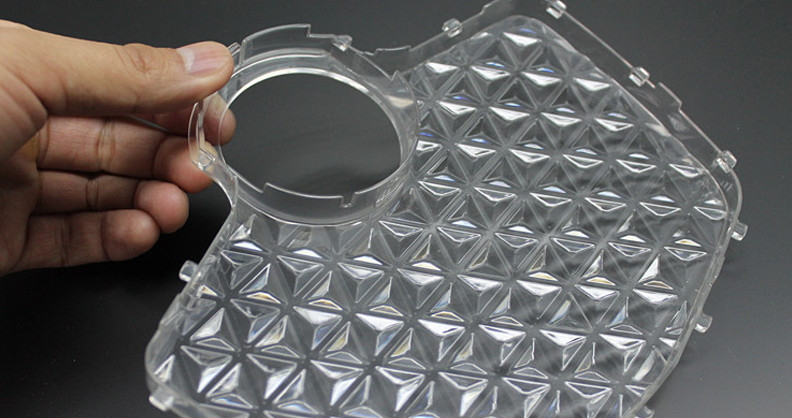

Silicone remolding (also known as urethane vacuum casting) is an economical alternative to small batch injection molding of plastic parts and can be used to closely simulate the final molded part or finished product. Typically, molds are made of silicone rubber and use CNC or SLA parts as masters. These molds replicate every structural detail and surface texture of the product, replicating another product by turning the mold over, and one set of silicone molds can replicate 10-15 sets of products.

Silicone replica mold material:

Polyurethane resins are polymers with a wide range of properties and uses. We offer a variety of urethane materials to meet your application, including Hei-Cast from Japan and Axson from France. are materials with certain properties similar to engineering production plastics such as ABS, PMMA, PC, PP, PA, and others. Cast parts can range from transparent, translucent to colored, and from soft rubber to hard plastic. The various materials include impact resistant, high temperature resistant (120°C) or fire resistant (UL94-V0), glass filled resins and silicone in different hardnesses.

ABS (black/primary color) remolding

PC/PMMA (Acrylic) Material

Silicone/TPU Soft

|

Standard Accuracy highest accuracy up to ±0.05mm. |

Maximum part size |

Minimum wall thickness |

|

Life span of silicone molds |

Standard Lead Time |

Surface treatment and other functions |

There are three major steps in the molding process:

Step 1. Prototyping Based on your CAD designed 3D drawings, we usually make the initial prototype using CNC machining or 3D printing (e.g. SLA/SLS), and then take it to open the replica mold after post-processing to put the prototype’s structural fit and surface finish in place.

Step 2. Make Silicone Molds The master model is hung in a box and plastic rods are placed to set up doors and vents. Silicone is poured around the master and a vacuum is used to remove all air. It is then cured in an oven at a temperature of 40°C. The molds are made in the same way as the masters. Depending on the volume of the mold, this usually takes 8-16 hours. Once the silicone rubber has cured, the master is removed from the silicone to form the cavity and create the silicone mold.

Step 3. Duplicate Product The resin is poured into the mold in the vacuum chamber under computer control and cured again in the oven. Average curing time: 1-3 hours for small parts and 3-6 hours for large parts. After curing remove the casting from the silicone mold. Repeat the cycle.

Advantages of vacuum remolding:

– Low mold cost

– Molds can be made in a few days

– Wide range of molding materials for a wide variety of applications

– The finished mold is accurate and has excellent surface finish.

– Durable molds that can be reproduced 15 times or more.

– Ideal for engineering models, samples, rapid prototypes, bridge to production

Low Pressure Infusion

Low Pressure Infusion (Reaction Injection Moulding) is also known as low pressure reaction injection molding. It is a new process applied to the production of rapid molded products. It has the advantages of high efficiency, short production cycle, simple process and low cost. Applicable to product development in the process of small batch trial production, as well as small batch production, the structure of the simpler cover parts and large-scale production of thick-walled and uneven wall thickness products. Generally used for automobile and medical and other large plastic hand plate shell production use.

Technical parameters:

– Applicable molds: ABS molds (more than 100 pieces); resin molds (more than 300 pieces); aluminum alloy molds (more than 1000 pieces).

– Pouring material: two-component polyurethane PU. materials used: HD-PU4210, DCP-RIM, AXSON-RIM 875.

– Physical Properties: similar to PP/ABS. the product has the characteristics of aging resistance, strong impact resistance, high anastomosis, easy loading and unloading, and so on.

– Injection pressure: about 10MPa. Flow control: 600g/s.

– General working time: 15-30 minutes/piece, demolding temperature can be controlled below 40℃, after demolding the parts are cured in 80℃ environment for 2-4 hours for the best performance.

– Standard reproduction accuracy: ±0.20mm/100mm.

– Thickness of pouring sample: The best pouring thickness is 4~6mm, the maximum pouring thickness is 30mm.

– Maximum casting workpiece: 2000mmX1200mmX1000mm, 20KG.